1. Technical Description

Successfully developed innovative technologies with independent intellectual property rights, such as "Acetylene Hydrogenation to Ethylene Process Technology," "Catalyst Technology for High-Concentration Acetylene Hydrogenation to Ethylene," and "Control Technology for Acetylene Hydrogenation Slurry Bed Reactor."

2. Technical Features

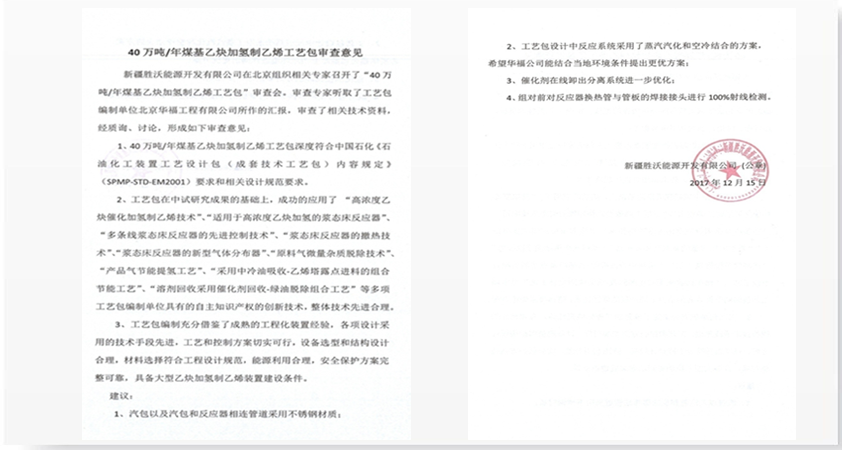

Using computational simulation as an auxiliary means, the process conditions were optimized, and a 5 million tons per year pilot plant was established; the preparation of a 4 million tons per year coal-based acetylene hydrogenation to ethylene process package was completed.

3. Technology Application

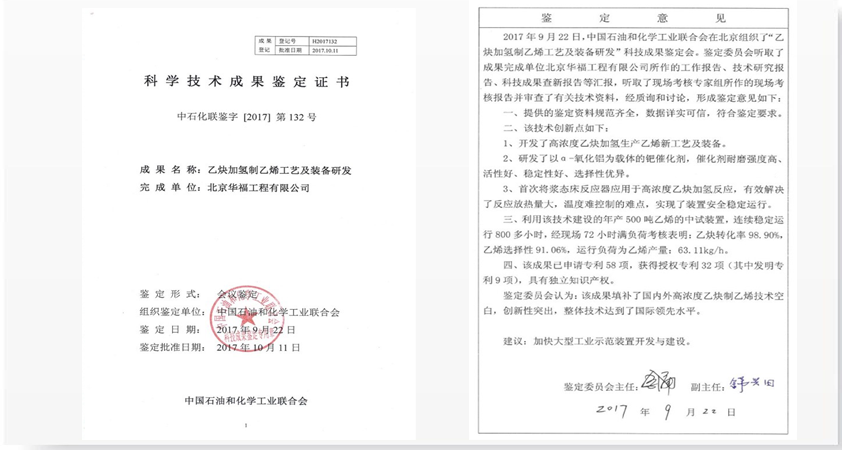

The "Research and Development of Acetylene Hydrogenation to Ethylene Process and Equipment" achievement was appraised by the China Petroleum and Chemical Industry Federation in 2017. The appraisal conclusion stated: "The achievement fills the technological gap for high-concentration acetylene to ethylene conversion both domestically and internationally, demonstrates outstanding innovation, and reaches an internationally leading level in overall technology."

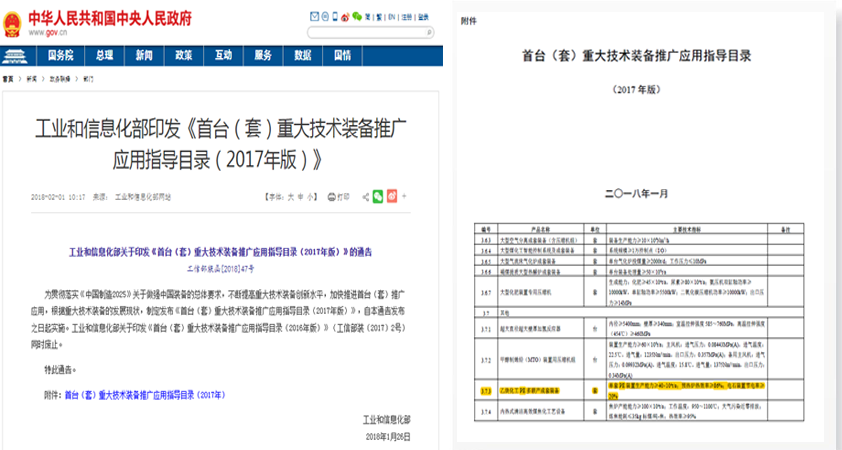

4. Technology Recognition

On September 22, 2017, the China Petroleum and Chemical Industry Federation organized an expert team led by Academician Jin Yong and Shu Xingtian, serving as the director and deputy director of the Expert Committee, to conduct a scientific and technological achievement evaluation of the acetylene hydrogenation to ethylene process and equipment research and development technology. The evaluation conclusion was that "this achievement fills the technological gap in the production of ethylene from high-concentration acetylene both domestically and internationally, with outstanding innovation, and the overall technology has reached the international leading level."

This technology has independently developed an acetylene hydrogenation process package for the production of 400,000 tons per year of polyethylene, and it has been applied industrially.